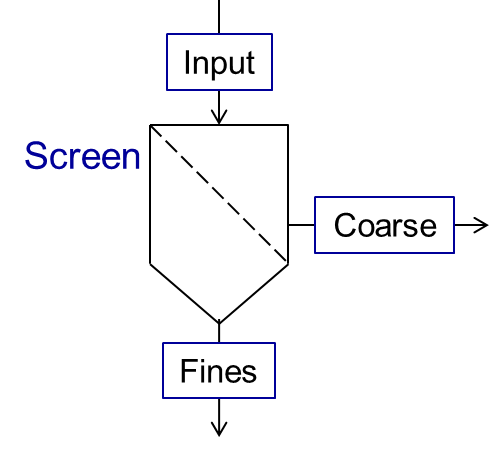

Screen

Screen unit is designed for classification of input material into two fractions according to particle size distribution (PSD), as shown below.

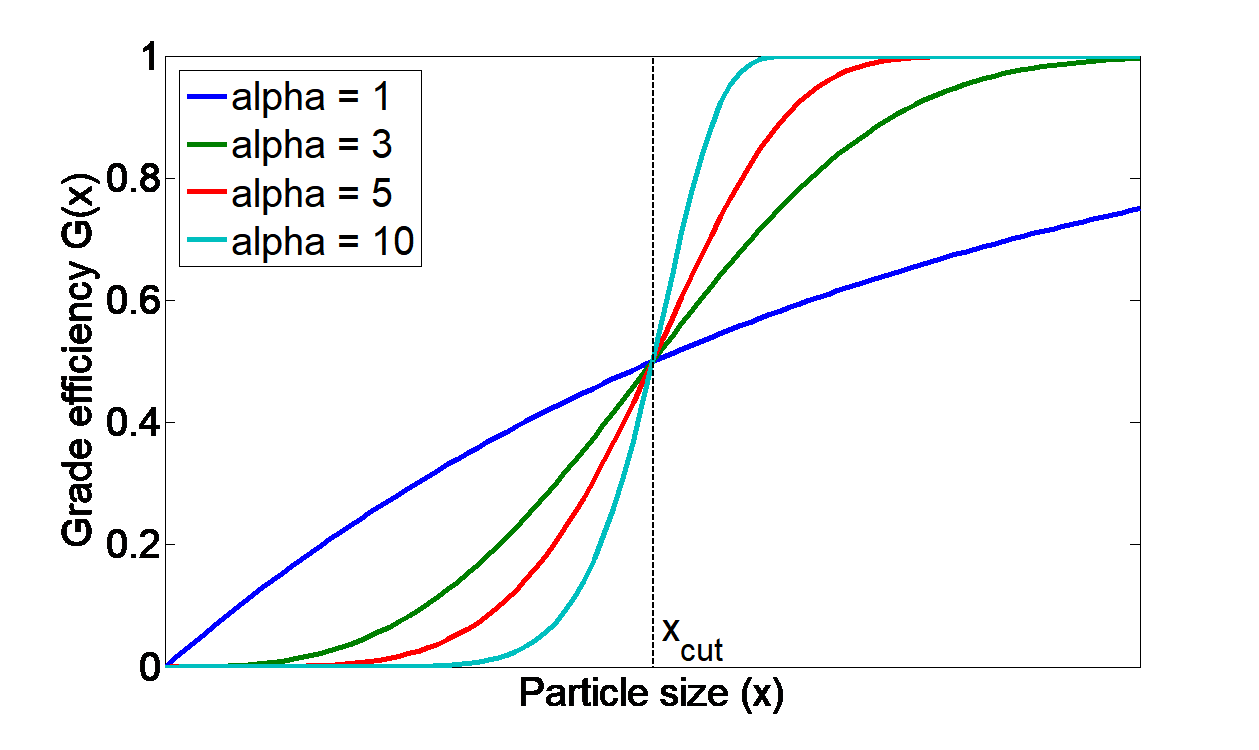

There are several models available to describe the screen grade efficiency:

In the following figure, several grade efficiency curves for different parameters of separations sharpness are shown.

Note

This figure only applies to the Plitt’s model and Molerus & Hoffmann model.

The output mass flows are calculated as follows:

Note

Notations:

Symbol |

Units |

Description |

|---|---|---|

\(\dot{m}_{out,c}\) |

[kg/s] |

Mass flow at the coarse output |

\(\dot{m}_{out,f}\) |

[kg/s] |

Mass flow at the fine output |

\(\dot{m}_{in}\) |

[kg/s] |

Feed mass flow |

\(G(x_i)\) |

[kg/kg] |

Grade efficiency: mass fraction of material of size class \(i\) in the feed that leaves the screen in the coarse stream |

\(w_{in,i}\) |

[kg/kg] |

Mass fraction of material of size class \(i\) in the feed |

Plitt’s model

This model is described using the following equation:

Note

Notations applied in the models:

\(G(x_i)\) – grade efficiency

\(x_{cut}\) – cut size of the classification model

\(\alpha\) – sharpness of separation

\(x_i\) – size of a particle

Note

Input parameters needed for the simulation:

Name |

Symbol |

Description |

Units |

Boundaries |

|---|---|---|---|---|

Xcut |

\(x_{cut}\) |

Cut size of the classification model |

[m] |

Xcut > 0 |

Alpha |

\(\alpha\) |

Sharpness of separation |

[–] |

0 ≤ Alpha ≤ 100 |

See also

a demostration file at Example Flowsheets/Units/Screen Plitt.dlfw.

See also

Plitt, L.R.: The analysis of solid–solid separations in classifiers. CIM Bulletin 64 (708), p. 42–47, 1971.

Molerus & Hoffmann model

This model is described using the following equation:

Note

Notations applied in the models:

\(G(x_i)\) – grade efficiency

\(x_{cut}\) – cut size of the classification model

\(\alpha\) – sharpness of separation

\(x_i\) – size of a particle

Note

Input parameters needed for the simulation:

Name |

Symbol |

Description |

Units |

Boundaries |

|---|---|---|---|---|

Xcut |

\(x_{cut}\) |

Cut size of the classification model |

[m] |

Xcut > 0 |

Alpha |

\(\alpha\) |

Sharpness of separation |

[–] |

0 < Alpha ≤ 100 |

See also

a demostration file at Example Flowsheets/Units/Screen Molerus-Hoffmann.dlfw.

See also

Molerus, O.; Hoffmann, H.: Darstellung von Windsichtertrennkurven durch ein stochastisches Modell, Chemie Ingenieur Technik, 41 (5+6), 1969, pp. 340-344.

Probability model

This model is described using the following equation:

Note

Notations applied in this model:

\(G(x_i)\) – grade efficiency

\(x_i\) – size of a particle

\(\sigma\) – standard deviation of the normal output distribution

\(\mu\) – mean of the normal output distribution

\(N\) – number of classes of particle size distribution

Note

Input parameters needed for the simulation:

Name |

Symbol |

Description |

Units |

Boundaries |

|---|---|---|---|---|

Mean |

\(\mu\) |

Mean of the normal output distribution |

[m] |

Mean > 0 |

Standard deviation |

\(\sigma\) |

Standard deviation of the normal output distribution |

[m] |

Standard deviation > 0 |

See also

a demostration file at Example Flowsheets/Units/Screen Probability.dlfw.

See also

Radichkov, R.; Müller, T.; Kienle, A.; Heinrich, S.; Peglow, M.; Mörl, L.: A numerical bifurcation analysis of continuous fluidized bed spray granulation with external product classification, Chemical Engineering and Processing 45, 2006, pp. 826–837.

Teipel / Hennig model

This model is described using the following equation:

Note

Notations applied in the models:

\(G(x_i)\) – grade efficiency

\(x_{cut}\) – cut size of the classification model

\(\alpha\) – sharpness of separation

\(\beta\) - sharpness of separation

\(a\) - separation offset

\(x_i\) – size of a particle

Note

Input parameters needed for the simulation:

Name |

Symbol |

Description |

Units |

Boundaries |

|---|---|---|---|---|

Xcut |

\(x_{cut}\) |

Cut size of the classification model |

[m] |

Xcut > 0 |

Alpha |

\(\alpha\) |

Sharpness of separation 1 |

[–] |

0 < Alpha ≤ 100 |

Beta |

\(\beta\) |

Sharpness of separation 2 |

[–] |

0 < Beta ≤ 100 |

Offset |

\(a\) |

Separation offset |

[–] |

0 ≤ Offset ≤ 1 |

See also

a demostration file at Example Flowsheets/Units/Screen Teipel-Hennig.dlfw.

See also

Hennig, M. and Teipel, U. (2016), Stationäre Siebklassierung. Chemie Ingenieur Technik, 88: 911–918.