For models developers

In Dyssol, you can develop and debug new steady-state or dynamic units as well as your own external modules (solvers).

The installation package of Dyssol contains all necessary components for the development of such modules. It is provided with a pre-configured solution for IDE Microsoft Visual Studio 2015 (or its Community edition).

The development of modules for Dyssol can be done in three following steps:

Copy template project with necessary header files and libraries from Dyssol installation path to desired folder and configure project.

Copy template of the necessary unit (dynamic or steady-state) or solver, rename it and add this module to the previously copied template project.

Reimplement all necessary functions. In the case of dynamic units the internal DAE/NL solver can be used to solve DAE/NL systems automatically. For detailed information about implementation of units and solvers, please refer to Unit development and Solver development.

Configuration of Visual Studio project template

Open directory where Dyssol has been installed (for example

C:\Program Files (x86)\Dyssol) and copy folderModelsCreatorSDKto the desired location on your hard drive (further as<PathToSolution>).Open the copied folder

ModelsCreatorSDKand run fileDyssol.slnto open solution in Microsoft Visual Studio, which should be previously installed.Select startup project:

Select project ModelsAPI in solution explorer, then choose Project → Set as StartUp Project.

Select paths to executable files:

Select project ModelsAPI in solution explorer, then choose Project → Properties → Configuration Properties → Debugging

Set combo box Configuration in the top of the window to position Debug, and provide the property Command with the path to debug version of executable, which is located at

<PathToSolution>\ModelsCreatorSDK\ExecutableDebug\Dyssol.exeSet combo box Configuration in the top of the window to position Release, and provide the property Command with the path to release version of executable, which is located in the directory where Dyssol has been installed:

C:\Program Files (x86)\Dyssol\Dyssol.exe

Set combo box Configuration in the top of the window to position Debug. Press F7 (or Build → Build project in program menu) to build core project and wait until the solution is built.

Press F5 (or Debug → Run debug in program menu) to run program in debug mode. New window of Dyssol should now be opened.

Close Dyssol window.

Visual Studio solution is now ready to create and debug your own modules.

Unit development

You must do the following in order to develop your new solver (plese refer to Configuration of Visual Studio project template):

Install Microsoft Visual Studio 2015 (Community).

Configure template project

ModelsCreatorSDK.

There are 4 different pre-defined templates of units available:

SteadyState: performs steady-state calculation; current state of such unit does not depend on the previous state, but only on the input parameters.

SteadyStateWithNLSolver: steady-state unit with connected internal solver of non-linear equations.

Dynamic: performs dynamic calculation; current state of this unit depends not only on the input parameters as well as on the previous state of the unit.

DynamicWithDAESolver: dynamic unit with connected internal solver of differential-algebraic equations.

Please also refer to Basic unit for detailed informaiton on functions applied in unit development.

Add new unit to the template project

Copy the desired template of the unit from

<PathToSolution>\ModelsCreatorSDK\UnitsTemplatesto the folderUnitsin solution (<PathToSolution>\ModelsCreatorSDK\Units).Rename template’s folder according to the name of your new unit (further

<MyUnitFolder>). The name can be chosen freely.Rename project files in template’s folder (

*.vcxproj,*.vcxproj.filters) according to the name of your new unit.Run the solution file (

<PathToSolution>\ModelsCreatorSDK\Dyssol.sln) to open it in Visual Studio.Add project with your new unit to the solution. To do this, select in Visual Studio File → Add → Existing Project and specify path to the project file (

<PathToSolution>\ModelsCreatorSDK\Units\<MyUnitFolder>\<*.vcxproj>).Rename added project in Visual Studio according to the name of your unit.

Now you can implement functionality of your new unit. To build your solution press F7, to run it in debug mode press F5. Files with new units will be placed to <PathToSolution>\ModelsCreatorSDK\Debug.

As debug versions of compiled and built units contain a lot of additional information, which is used by Visual Studio to perform debugging, their calculation efficiency can be dramatically low. Thus, for the simulation purposes, units should be built in Release mode.

Configure Dyssol to work with implemented units

Build your units in Release mode. To do this, open your solution in Visual Studio (run file

<PathToSolution>\ModelsCreatorSDK.sln), switch Solution configuration combo box from the toolbox of Visual Studio from Debug to Release and build the project (press F7 or choose Build → Build project in program menu).Configure Dyssol by adding the path to new units: run Dyssol, choose Tools → Models Manager and add path to your models (

<PathToSolution>\ModelsCreatorSDK\Release).

Now, all newly developed units will be available in Dyssol.

In general, usual configuration of Models Manager should include following path for units:

<InstallationPath>\Units: list of standard units;

<PathToSolution>\ModelsCreatorSDK\UnitsDebugLibs: debug versions of standard units;

<PathToSolution>\ModelsCreatorSDK\Debug: debug versions of developed units;

<PathToSolution>\ModelsCreatorSDK\Release: release versions of developed units.

Development of steady-state units

Unit::CUnit()

Constructor of the unit: called only once when unit is added to the flowsheet. In this function a set of parameters should be specified:

Basic info:

m_sUnitName: Name of the unit that will be displayed in Dyssol.m_sAuthorName: Unit’s authorm_sUniqueID: Unique identificator of the unit. Simulation environment distinguishes different units with the help of this identificator.

You must ensure that ID of your unit is unique. This ID can be created manually or using GUID-generator of Visual Studio (Tools → GUID Genarator).

Specify ports for stream in- and outlet(s): add new, rename or delete existing.

Additional internal material streams can be defined here.

Sepcify unit parameters.

All other operations, which should take place only once during the unit’s creation.

Unit::~CUnit()

Destructor of the unit: called only once when unit is removed from the flowsheet. Here all memory which has been previously allocated in the constructor should be freed.

void CUnit::Initialize(double _dTime)

Unit‘s initialization. This function is called only once at the start of the simulation at time point dTime. Starting from this point, information about defined compounds, phases, distributions, etc. are available for the unit. Here you can create state variables and initialize some additionaly objects (e.g. additional material streams, state variables or plots).

void CUnit::Simulate(double _dTime)

Steady-state calculation for a specified time point dTime. This function is called iteratively for all time points for which this unit should be calculated. All main calculations should be implemented here.

void CUnit::Finalize()

Unit‘s finalization. This function is called only once at the end of the simulation. Here one can perform closing and cleaning operations to prepare for the next possible simulation run. Implementation of this function is not obligatory and can be skipped.

Application example

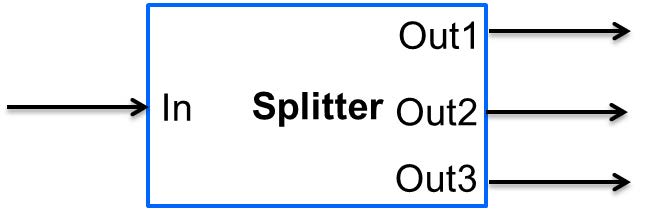

Now you want to develop a new steady-state model of splitter with one input stream and three output streams, as the figure shown below. The splitting factors for the first and second outlets are \(k_1\) and \(k_2\) respectively.

You need the following steps:

Copy the directory with the template unit

<PathToSolution>\ModelsCreatorSDK\UnitsTemplates\SteadyStateUnitto the directory for new units<PathToSolution>\ModelsCreatorSDK\Units\.Rename the copied template’s directory

SteadyStateUnittoMySplitter. Open the directoryMySplitterand rename fileSteadyState.vcxprojtoMySplitter.vcxproj.Open the template solution

<PathToSolution>\ModelsCreatorSDK\Dyssol.slnin Visual Studio.Add project with your new unit to the solution: select in Visual Studio File → Add → Existing Project and specify path to the project file

<PathToSolution>\ModelsCreatorSDK\Units\MySplitter\MySplitter.vcxproj.Rename added project in Visual Studio from

UnitT_SteadyStatetoUnit_MySplitter.Open

Unit_MySplitter→Unit.cppin the Visual Studio’s Solution Explorer and extend the unit with the following functionality (please refer to Basic unit, Stream and PSD functions when necessary):

Modify constructor

CUnit():Specify unit’s name by changing value of variable

m_sUnitNametoMy Splitter. This name will appear in the drop-down list for unit types in Dyssol simulation.Specify author’s name by changing value of variable

m_sAuthorName.Set new unique key of the unit by changing value of variable

m_sUniqueIDto some random string. To generate such a string GUID generator of Visual Studio can be used Tools → Create GUID.Add two additional output ports and rename all of them.

CUnit::CUnit() { // Basic unit's info m_sUnitName = "MySplitter"; m_sAuthorName = "MyName"; m_sUniqueID = "B59F8349A7014AC294D6580C0D8E21FE"; // Add ports AddPort("In", INPUT_PORT); AddPort("Out1", OUTPUT_PORT); AddPort("Out2", OUTPUT_PORT); AddPort("Out3", OUTPUT_PORT); // Add unit parameters - splitting factors AddConstParameter("k1", 0, 1, 0, "k1"); AddConstParameter("k2", 0, 1, 0, "k2"); }

Modify function

Initialize(): remove all codes in it.Modify function

Simulate():Here you should perform all steps which are needed in the simulaition, including get port streams, set mass flow of inlet streams and the calculation of output streams. Also don’t forget to give user warning if some streams becomes minus.

void CUnit::Simulate(double _dTime) { // Get streams of all ports and assign them to corresponding material streams CMaterialStream* pInStream = GetPortStream("In"); CMaterialStream* pOutStream1 = GetPortStream("Out1"); CMaterialStream* pOutStream2 = GetPortStream("Out2"); CMaterialStream* pOutStream3 = GetPortStream("Out3"); // Copy inlet stream to all outlet streams pOutStream1->CopyFromStream(pInStream, _dTime); pOutStream2->CopyFromStream(pInStream, _dTime); pOutStream3->CopyFromStream(pInStream, _dTime); // Set mass flow rate of inlet stream double dMassFlowIn = pInStream->GetMassFlow(_dTime); // Add splitting factors double dSplitFactor1 = GetConstParameterValue("k1"); double dSplitFactor2 = GetConstParameterValue("k2"); // Give warning if sum of splitting factors is greater than 1 if (dSplitFactor1 + dSplitFactor2 > 1) RaiseError("Warning about minus outlet 3..."); // Set calculated mass flow rate to corresponding outlet streams pOutStream1->SetMassFlow(_dTime, dMassFlowIn * dSplitFactor1); pOutStream2->SetMassFlow(_dTime, dMassFlowIn * dSplitFactor2); pOutStream3->SetMassFlow(_dTime, dMassFlowIn * (1 - dSplitFactor1 - dSplitFactor2)); }

Perform test simulation:

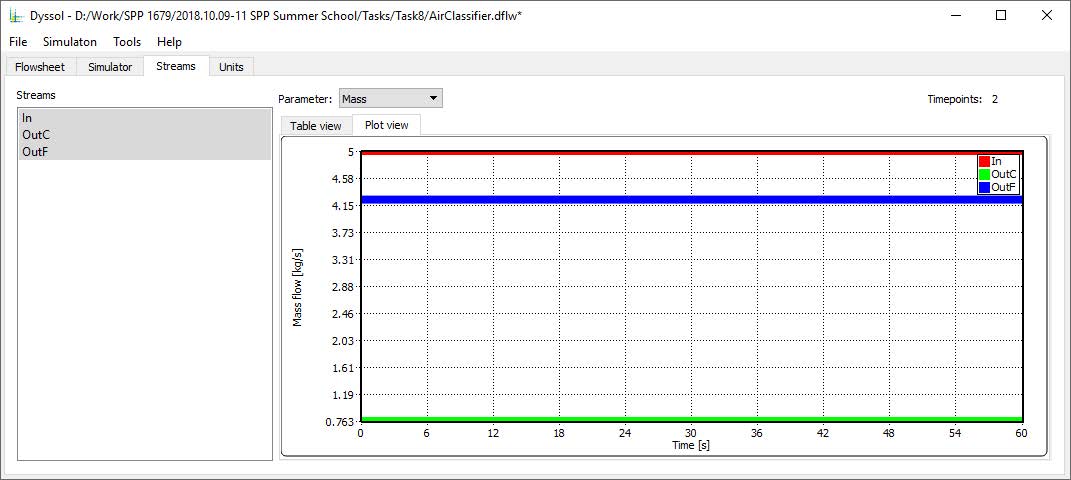

Now you have your complete code for the splitter. Build the solution and then run Dyssol in debug mode. Add material streams and the unit, choose the unit type “MySplitter”, set inlet mass flow and splitting factors according to the table below, and finally check if the results are correct. Finally, save the simulation file for the example of developing a dynamic unit.

General

Materials

Sand

Phases

Solid

Inlet

Time points

0 s

Mass stream

1 kg/s

Phase mass fractions

Solid: 1

Compounds mass fractions

Sand: 1

Options

Simulation time

60 s

Development of steady-state units with internal non-linear solver

You can solve nonlinear equation systems automatically in Dyssol system. In this case, the unit should contain one or several additional objects of CNLModel class. This class is used to describe non-linear systems and can be automatically solved with CNLSolver class.

Unit::Unit()

Constructor of the unit: called only once when unit is added to the flowsheet. In this function a set of parameters should be specified:

Basic info:

m_sUnitName: Name of the unit that will be displayed in Dyssol.m_sAuthorName: Unit’s authorm_sUniqueID: Unique identificator of the unit. Simulation environment distinguishes different units with the help of this identificator.

You must ensure that ID of your unit is unique. This ID can be created manually or using GUID-generator of Visual Studio (Tools → GUID Genarator).

Specify ports for stream in- and outlet(s): add new, rename or delete existing.

Additional internal material streams can be defined here.

Sepcify unit parameters.

All other operations, which should take place only once during the unit’s creation.

Unit::~Unit()

Destructor of the unit: called only once when unit is removed from the flowsheet. Here all memory which has been previously allocated in the constructor should be freed.

Unit::Initialize(double _dTime)

Unit‘s initialization. This function is called only once at the start of the simulation at time point dTime. Starting from this point, information about defined compounds, phases, distributions, etc. are available for the unit. Here you can create state variables and initialize some additionaly objects (for example holdups, material streams, state variables or plots).

In this function, variables of all NLModels should be specified by using function NLModel::AddNLVariable(); connection between NLModel and NLSolver classes should be created by calling function NLSolver::SetModel().

Unit::Simulate(double _dTime)

Steady-state calculation for a specified time point dTime. This function is called iteratively for all time points for which this unit should be calculated. All main calculations should be implemented here. Calculation of the defined NL-system can be run here by calling function NLSolver::Calculate().

Unit::SaveState()

For flowsheets containing recycled streams, SaveState() function is called when the convergence on the current time interval is reached, this also ensures the return to the previous state of the unit if convergence fails during the calculation. Here all internal time-dependent variables which weren’t added to the unit by using AddStateVariable and AddMaterialStream functions should be manually saved. Implementation of this function is not obligatory and can be skipped.

Unit::LoadState()

Load last state of the unit which has been saved with SaveState() function. Implementation of this function is not obligatory and can be skipped.

Unit::Finalize()

Unit‘s finalization. This function is called only once at the end of the simulation. Here one can perform closing and cleaning operations to prepare for the next possible simulation run. Implementation of this function is not obligatory and can be skipped.

NLModel::CalculateFunctions(double* _pVars, double* _pFunc, void* _pUserData)

Here the non-linear system should be specified. This function will be called by solver automatically.

NLModel::ResultsHandler(double _dTime, double* _pVars, void* pUserData)

Handling of results, which are returned from NLSolver on each time point. Called by solver every time when the solution in a new time point is ready.

Application example

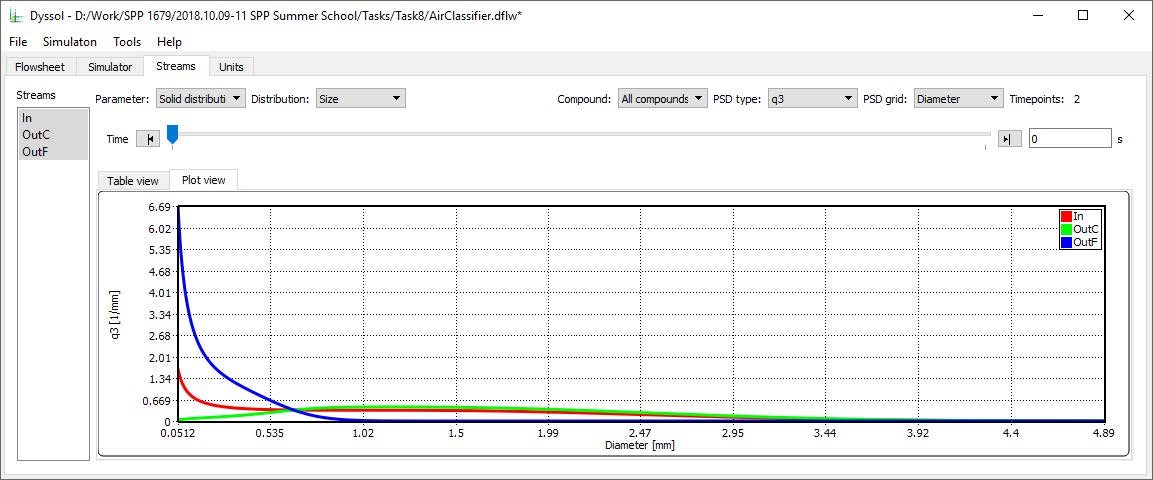

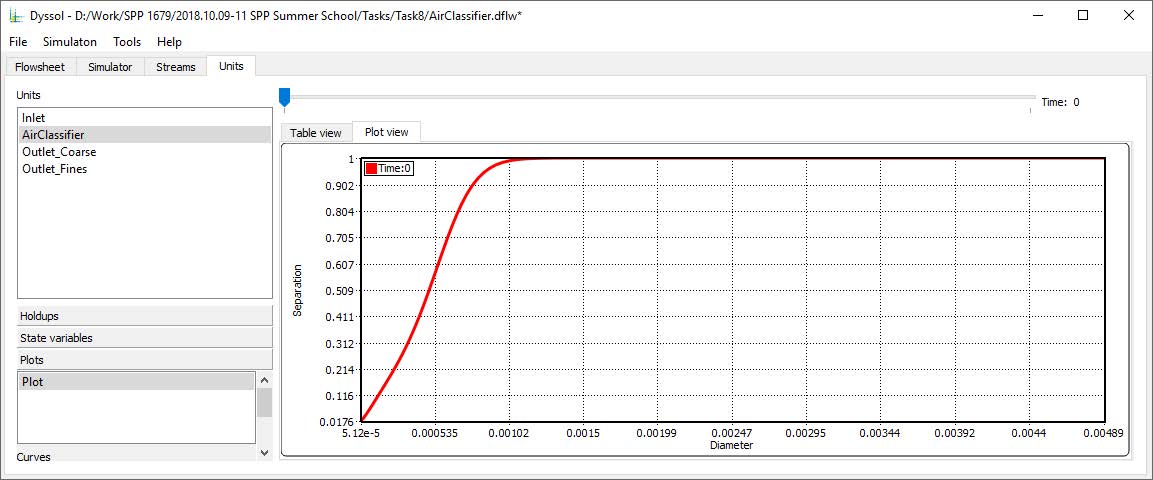

In this example, you need to develop a steady-state unit for a simple air classifying process, which separates particles according to their sinking velocity in a fluid stream. Additionally, the time and particle size dependence of separation efficiency should be plotted.

The separation depends on the relative velocity between the fluid and the particles \(v_{rel,i} = u_G - v_{P,i}\). Floating particles with no velocity, i.e. \(v_{rel,i} = u_G\), will be divided evenly to coarse and fines stream.

The separation efficiency and cut-off velocity are defined as in the formulas below.

To complete the simulation, you need to solve the following implicit equation system:

Note

Notations:

\(v_{rel,i}\) – Relative velocity of particle of size class \(i\) [m/s]

\(v_{P,i}\) – Velocity of particle of size class \(i\) [m/s]

\(u_G\) – Velocity of gas [m/s]

\(\xi_{C,i}\) – Separation efficiency of size class \(i\) [-]

\(w_{cut}\) – Cut-off velocity [m/s]

\(\dot{m}_G\) – Gas mass flow [kg/s]

\(Re_{P,i}\) – Reynolds number of size class \(i\) [-]

\(d_{P,i}\) – Particle diameter of size class \(i\) [m]

\(C_{W,P,i}\) – Drag coefficient of size class \(i\) [-]

\(\rho_G\) – Gas density [\(kg/m^3\)]

\(\rho_P\) – Particle / solid density [\(kg/m^3\)]

\(\eta_G\) – Gas dynamic viscosity [Pa·s]

\(x\) – Sharpness factor [-]

\(A\) – Cross-sectional area [\(m^2\)]

\(g\) – Gravitational acceleration [\(m/s^2\)]

Now you need the following steps:

Copy the directory with the template unit

<PathToSolution>\ModelsCreatorSDK\UnitsTemplates\SteadyStateWithNLSolver\to the directory for new units<PathToSolution>\ModelsCreatorSDK\Units\. Rename the folder toAirClassifierTemplateand the fileSteadyStateWithNLSolver.vcxprojtoAirClassifier.vcxproj.Along with this application example, you obtain a pre-configured template folder of the air classifier unit

...\Task8\AirClassifierTemplate\, in which you find the source fileUnit.cppand header fileUnit.h. Copy the contents of them to the correspondingUnit.cppandUnit.hfiles in your template folder<PathToSolution>\ModelsCreatorSDK\Units\AirClassifierTemplate\.Open the template solution

<PathToSolution>\ModelsCreatorSDK\Dyssol.slnin Visual Studio.Add project with your new unit to the solution: select File → Add → Existing Project and specify path to the project file

<PathToSolution>\ModelsCreatorSDK\Units\AirClassifierTemplate\. Rename the unit toUnit_AirClassifier.Open

Unit_AirClassifier→Unit.cppin the Visual Studio’s and extend the unit with the following functionality:

Edit the unit

CUnit:Modify constructor

CUnit():Specify unit’s name by changing value of variable

m_sUnitNametoAir classifier. This name will appear in the drop-down list for unit types in Dyssol simulation.Specify author’s name by changing value of variable

m_sAuthorName.For

m_sUniqueID, unlike the examples in steady-state unit, DO NOT change the ID, because the given ID is connected with the simulation file provided. If you change the ID, the parameter in simulation file would not be read by Dyssol and you can’t carry out your simulaiton.Add 2 unit parameters using function

AddConstParameter: the cross-sectional area A ranging between 0.01 and 100, and the sharpness factor x ranging between 0.01 and 10. You can set inital value to 1 for both parameters.

You find the example code below:

CUnit::CUnit() { // Basic unit's info m_sUnitName = "Air classifier"; m_sAuthorName = "Your name"; m_sUniqueID = "211D0E54C80A4F3EB464671EEA222932"; // DO NOT change this ID // Add ports AddPort("Input", INPUT_PORT); AddPort("Coarse", OUTPUT_PORT); AddPort("Fines", OUTPUT_PORT); // Add unit parameters AddConstParameter("A", 0.01, 100, 1, "Area"); // A AddConstParameter("x", 0.01, 10, 1, "Sharpness"); // x // Add user data to model m_NLModel.SetUserData(this); }

Modify function

Initialize():Get the number of size classes (

GetClassesNumber(DISTR_SIZE)) and save them to variablenum_classes.For each particle size class add a non-linear variable to the model (

AddNLVariable) with initial value 1 and no constraints.Add a plot to the unit for the separation efficiency: Separation (Y axis is “Separation”) against diameter (X axis is “Diameter”) and time (Z axis is “Time”).

The finished code of the function is shown below.

void CUnit::Initialize(double _dTime) { // Check Simulation Setup if (!IsPhaseDefined(SOA_VAPOR)) { RaiseError("Gas phase not defined."); // Check for gas phase } if (!IsPhaseDefined(SOA_SOLID)) { RaiseError("Solid phase not defined."); // Check for solid phase } if (!IsDistributionDefined(DISTR_SIZE)) { RaiseError("Particle size distribution not defined."); // Check for size distribution } // Clear all state variables in model m_NLModel.ClearVariables(); // Get number of diameter classes unsigned num_classes = GetClassesNumber(DISTR_SIZE); // Add variable to the model of nonlinear equation system for(unsigned i = 0; i < num_classes; ++i) { m_NLModel.AddNLVariable(1.0, 0.0); // v_rel_i (relative velocity for each particle size class) } // Set model to the solver if (!m_NLSolver.SetModel(&m_NLModel)) { RaiseError(m_NLSolver.GetError()); } // Add Plot AddPlot("Plot", "Diameter", "Separation", "Time"); }

Edit the solver

CMyNLModel:Implement function

CalculateFunctions(double* _pVars, double* _pFunc, void* _pUserData): in this funciton, the updated values_pFuncof the non-linear variables_pVarsis computed until the residual between_pFuncand_pVarreaches a certain tolerance.Get pointer to the output streams to enable calculation with stream properties.

Get vector with particle diameters (

GetClassesMeans(DISTR_SIZE)) and store them to variabled.Get gas properties (

GetPhaseTPDProp()forDENSITYandVISCOSITY) at the time pointtime.Save current values of

_pVarsand save them to variablev_rel.Calculate variables

Re_i,Cwp_i,v_rel_update_iaccording to the equation system described above and save the value of the relative velocity to_pFunc.

The example code for this function looks like this:

void CMyNLModel::CalculateFunctions(double* _pVars, double* _pFunc, void* _pUserData) { // Get pointer to air classifier unit auto unit = static_cast<CUnit*>(_pUserData); // Get pointers to streams CMaterialStream* inStream = unit->GetPortStream("Input"); CMaterialStream* outStreamC = unit->GetPortStream("Coarse"); CMaterialStream* outStreamF = unit->GetPortStream("Fines"); // Overall parameter double g = 9.81; // graviational acceleration // Get diameter classes and their number unsigned num_classes = unit->GetClassesNumber(DISTR_SIZE); std::vector<double> d = unit->GetClassesMeans(DISTR_SIZE); // Get stream parameters double rho_solid = inStream->GetPhaseTPDProp(time, DENSITY, SOA_SOLID); double rho_gas = inStream->GetPhaseTPDProp(time, DENSITY, SOA_VAPOR); double eta_gas = inStream->GetPhaseTPDProp(time, VISCOSITY, SOA_VAPOR); // Get value of variables (v_rel_i) at current iteration of solver std::vector<double> v_rel; for (unsigned i = 0; i < num_classes; ++i) { v_rel.push_back(_pVars[i]); } // Calculation of new function values of relative velocity for (unsigned i = 0; i < num_classes; ++i) { // Reynolds number of particle classes Re_i double Re_i = (fabs(v_rel[i]) * d[i] * rho_gas) / eta_gas; // Drag coefficient of particle classes Cwp_i double Cwp_i = 24. / Re_i + 4. / std::sqrt(Re_i) + 0.4; // Relative velocity double v_rel_update_i = sqrt((4. * rho_solid * d[i] * g) / (3. * rho_gas * Cwp_i)); // Update function value _pFunc[i] = v_rel_update_i; } }

Implement function

ResultsHandler(double _dTime, double* _pVars, void* _pUserData): this function processes the results returned by the solver, after convergence is reached.Initialize output streams for fines by copying the information from input and afterwards setting the total mass flows to zero.

Get unit parameters for

Aandx(GetConstParameterValue).Get stream properties from input stream: solid and gas mass flows (

GetPhaseMassFlow) as well as particle size distribution (GetPSD).Calculate cut-velocity

w_cutaccording to the equation for it.Caculate the separation to the coarse stream

xiC_i:Save the value of the relative velocity to

v_rel_i.Calculate

xiC_iaccording to the equation for it.Calculate the accumulated mass fraction of coarse stream by adding up

xiC_imultiplied by incoming mass fraction of class \(i\),wIn[i].Update the Transformation matrices.

Save

xiC_ito vector for later plotting purposes.

Apply transformation matrices to output streams and set the phase mass flows. You need 2 matrices, one for coarse stream and the other for fine stream. Please also notice that all gases must leave with fine stream.

The matrices contain the separatiom efficiency

xiC_iof all size classes \(i\).TInputToCoarse: all elements NOT on diagonal are zero.xiC_iof classe \(i\) locates at position \((i,i)\).TInputToFine: all elements NOT on diagonal are zero.1 - xiC_iof classe \(i\) locates at position \((i,i)\).Plotting: Add a new curve to the plot (

AddCurveOnPlot) at time_dTimeand then add the points for separation (AddPointOnCurve).

You can find the example code for this function below:

void CMyNLModel::ResultsHandler(double _dTime, double* _pVars, void* _pUserData) { // Get pointer to air classifier unit auto unit = static_cast<CUnit*>(_pUserData); // Get pointers to streams CMaterialStream* inStream = unit->GetPortStream("Input"); CMaterialStream* outStreamC = unit->GetPortStream("Coarse"); CMaterialStream* outStreamF = unit->GetPortStream("Fines"); // Get diameter classes and their number std::vector<double> d = unit->GetClassesMeans(DISTR_SIZE); unsigned num_classes = unit->GetClassesNumber(DISTR_SIZE); // Initialize output streams: // Setting total mass flow to zero allows only for ... // ... setting phase mass flows at the end of the unit // (total mass flow will be calculated automatically) outStreamC->CopyFromStream(inStream, _dTime); outStreamC->SetMassFlow(_dTime, 0); outStreamF->CopyFromStream(inStream, _dTime); outStreamF->SetMassFlow(_dTime, 0); // Setup transformation matrices CTransformMatrix TInputToCoarse(DISTR_SIZE, num_classes); CTransformMatrix TInputToFines(DISTR_SIZE, num_classes); // Get parameters double A = unit->GetConstParameterValue("A"); double x = unit->GetConstParameterValue("x"); // Get stream parameters double dm_solid = inStream->GetPhaseMassFlow(_dTime, SOA_SOLID); double rho_solid = inStream->GetPhaseTPDProp(_dTime, DENSITY, SOA_SOLID); double dm_gas = inStream->GetPhaseMassFlow(_dTime, SOA_VAPOR); double rho_gas = inStream->GetPhaseTPDProp(_dTime, DENSITY, SOA_VAPOR); std::vector<double> wIn = inStream->GetPSD(_dTime, PSD_MassFrac); // Calculate cut velocity double w_cut = dm_gas / (rho_gas * A); // Calculate separation efficiency: // Fraction of mass in coarse stream double wC_acc = 0; // Separation efficiency for each particle class std::vector<double> xiC; for (unsigned i = 0; i < num_classes; ++i) { // Get value of variables (v_rel_i) after convergence of solver double v_rel_i = _pVars[i]; // Temporary value for separation of particle class to coarse stream double xiC_i; // Check values of relative velocity: // If v_rel_i < 0, particles are faster than fluid, i.e. they will go to fines // Else calculate separation based on functions if (v_rel_i < 0) { xiC_i = 0; } else { double temp_exp = exp( x * (1 - pow(v_rel_i / w_cut, 3))); xiC_i = 1. / (1 + w_cut / v_rel_i * temp_exp); } // Update fraction of mass that goes to coarse stream wC_acc += wIn[i] * xiC_i; // Update transformation matrices of the separation TInputToCoarse.SetValue(i, i, xiC_i); TInputToFines.SetValue(i, i, 1 - xiC_i); // Save temporary separation value to vector xiC.push_back(xiC_i); } // Set properties of coarse stream: // Apply transformation matrix to coarse stream outStreamC->ApplyTM(_dTime, TInputToCoarse); // Set coarse solid mass flow outStreamC->SetPhaseMassFlow(_dTime, SOA_SOLID, wC_acc * dm_solid); // Set properties of fine stream: // Apply tranformation matrix to fines stream outStreamF->ApplyTM(_dTime, TInputToFines); // Set gas mass flow outStreamF->SetPhaseMassFlow(_dTime, SOA_VAPOR, dm_gas); // Set solid mass flow outStreamF->SetPhaseMassFlow(_dTime, SOA_SOLID, (1 - wC_acc) * dm_solid); // Plotting separation efficiency for coarse stream unit->AddCurveOnPlot("Plot", _dTime); unit->AddPointOnCurve("Plot", _dTime, d, xiC); }

Test the unit in Dyssol:

Build the solution and run Dyssol: Build → Build Solution, and then Debug → Start Debugging.

Use exemplary flowsheet

...\Tasks8\AirClassifier.dflwto test your unit. Compare your results with the expected ones below.

Development of dynamic units

Unit::Unit()

Constructor of the unit: called only once when unit is added to the flowsheet. In this function a set of parameters should be specified:

Basic info:

m_sUnitName: Name of the unit that will be displayed in Dyssol.m_sAuthorName: Unit’s authorm_sUniqueID: Unique identificator of the unit. Simulation environment distinguishes different units with the help of this identificator. You must ensure that ID of your unit is unique. This ID can be created manually or using GUID-generator of Visual Studio (Tools → GUID Genarator).

Specify ports for stream in- and outlet(s): add new, rename or delete existing.

Specify unit parameters.

Define internal holdups and additional material streams.

Define all other operations, which should take place only once during the unit’s creation.

Unit::~Unit()

Destructor of the unit: called only once when unit is removed from the flowsheet. Here all memory which has been previously allocated in the constructor should be freed.

Unit::Initialize(double _dTime)

Unit‘s initialization. This function is called only once at the start of the simulation at dTime. Starting from this point, information about defined compounds, phases, distributions, etc. are available for the unit. Here you can create state variables and initialize some additionaly objects (e.g. holdups, material streams or state variables).

Unit::Simulate(double _dStartTime, double _dEndTime)

Dynamic calculation of the unit on a specified time interval from dStartTime to dEndTime. All logic of the unit’s model must be implemented here.

Unit::SaveState()

For flowsheets containing recycled streams, SaveState() function is called when the convergence on the current time interval is reached, this also ensures the return to the previous state of the unit if convergence fails during the calculation. Here all internal time-dependent variables which weren’t added to the unit by using AddStateVariable, AddMaterialStream or AddHoldup functions should be manually saved. Implementation of this function is not obligatory and can be skipped.

Unit::LoadState()

Load last state of the unit which has been saved with the SaveState() function. Implementation of this function is not obligatory and can be skipped.

Unit::Finalize()

Unit‘s finalization. This function is called only once at the end of the simulation. Here one can perform closing and cleaning operations to prepare for the next possible simulation run. Implementation of this function is not obligatory and can be skipped.

Application example

You will learn to implement a simple dynamic unit (however without any physical meaning), where the basic functionality of classes CBaseUnit, CMaterialStream and CHoldup can be tested.

Do the following steps:

Copy a directory with the template unit

<PathToSolution>\ModelsCreatorSDK\UnitsTemplates\DynamicUnitto the directory for new units<PathToSolution>\ModelsCreatorSDK\Units\.Rename the copied template’s directory

DynamicUnittoBasics. Open the directoryBasicsand rename the file Dynamic.vcxproj` toBasics.vcxproj.Open the template solution (

<PathToSolution>\Dyssol.sln) in Visual Studio.Add project with your new unit to the solution: select in Visual Studio File → Add → Existing Project and specify path to the project file

<PathToSolution>\ModelsCreatorSDK\Units\Basics\Basics.vcxproj.Rename added project in Visual Studio from

UnitT_DynamictoUnit_Basics.Open

Unit_Basics→Unit.cppin the Visual Studio’s Solution Explorer and develop your unit as shown follows. You can use Basic unit, Stream and PSD functions for references.

Modify constructor

CUnit():Specify unit’s name by changing value of variable

m_sUnitNametoBasics. This name will appear in the drop-down list for unit types in Dyssol simulation.Specify author’s name by changing value of variable

m_sAuthorName.Set new unique key of the unit by changing value of variable

m_sUniqueIDto some random string. To generate such a string, you can use GUID generator of Visual Studio (Tools → Create GUID).

Now your code for constructor should look like this:

CUnit::CUnit() { // Basic unit's info m_sUnitName = "Basics"; m_sAuthorName = "Your name"; m_sUniqueID = "30D8887B8E5F4BF5B91B98342684E707"; // Add ports AddPort("InPort", INPUT_PORT); AddPort("OutPort", OUTPUT_PORT); // Add unit parameters AddTDParameter("ParamTD", 0, 1e+6, 0, "Unit parameter description"); AddConstParameter("ParamConst", 0, 1e+6, 0, "Unit parameter description"); AddStringParameter("ParamString", "Initial value", "Unit parameter description"); // Add holdups AddHoldup("HoldupName"); }

Modify function

Initialize(double _dTime):Add warnings if liquid or vapor phases are not defined. Use functions

IsPhaseDefinedandRaiseWarning.Add an internal material stream named “BufStream” using the function

AddMaterialStream.Add new plot with the name “Plot1” to show dependency of holdup’s mass (Y axis is “Mass”) over time (X axis is “Time”). Add a curve on this plot with the name “Curve1”. Use the functions

AddPlotandAddCurveOnPlot.

An example for this section is shown below.

void CUnit::Initialize(double _dTime) { /// Add state variables /// AddStateVariable("VarName", 0, true); if (!IsPhaseDefined(SOA_LIQUID)) { RaiseWarning("Liquid phase has not been defined"); } if (!IsPhaseDefined(SOA_VAPOR)) { RaiseWarning("Vapor phase has not been defined"); } // Add buffer stream AddMaterialStream("BufStream"); // Add plot AddPlot("Plot1", "Mass", "Time"); AddCurveOnPlot("Plot1", "Curve1"); }

Modify funciton

Simulate(double _dStartTime, double _dEndTime):Obtain pointer to the

BufStreaminto the new variableCMaterialStream *bufStream(with the functionGetMaterialStream).Add new time point

_dStartTimetoBufStreamwithbufStream->AddTimePoint.Copy inlet into BufStream at

_dEndTimewith the functionbufStream->CopyFromStream.Set mass flow to 12.5 kg/s of the liquid phase in BufStream at t = 10s (

bufStream->SetPhaseMassFlow).Add inlet to the holdup on entire time interval from _dStartTime to _dEndTime (

pHoldup->AddStream).Copy the holdup into the outlet for

_dStartTimetime point with mass flow 1 kg/s (pOutStream->CopyFromHoldup).Set new temperature T = 320 K to the outlet at t = 15 s (

pOutStream->SetTemperature).Plot mass of the holdup for all defined time points. Use the functions

GetAllDefinedTimePoints,AddPointOnCurveandpHoldup->GetMass.

The example code looks like follows:

void CUnit::Simulate(double _dStartTime, double _dEndTime) { // Get pointers to streams CMaterialStream* pInStream = GetPortStream("InPort"); CMaterialStream* pOutStream = GetPortStream("OutPort"); CMaterialStream* bufStream = GetMaterialStream("bufStream"); // Get pointers to holdups CHoldup* pHoldup = GetHoldup("Holdup"); // Add start time point to bufStream bufStream->AddTimePoint(_dStartTime); // Copy inlet stream into bufStream bufStream->CopyFromStream(pInStream, _dEndTime); // Set mass flow 12.5 kg/s of liquid phase in bufStream at time point 10 s bufStream->SetPhaseMassFlow(10, SOA_LIQUID, 12.5, BASIS_MASS); // Add inlet to the holdup on entire time interval pHoldup->AddStream(pInStream, _dStartTime, _dEndTime); // Copy the holdup into outlet stream at end time point with mass flow 1 kg/s pOutStream->CopyFromHoldup(pHoldup, _dStartTime, 1); // Set new temperature 320 K to outlet at time point 15 s pOutStream->SetTemperature(15, 320); // Plot holdup mass for all defined time points std::vector<double> times = GetAllDefinedTimePoints(_dStartTime, _dEndTime); for (int i = 0; i < times.size(); i++) { double x = times[i]; double y = pHoldup->GetMass(times[i], BASIS_MASS); AddPointOnCurve("Time dependence of holdup mass", "Curve1", x, y); } // Data acquisition: // Get unit parameters double TDParameter = GetTDParameterValue("ParamTD", 5); double ConstParameter = GetConstParameterValue("ParamConst"); std::string StringParameter = GetStringParameterValue("ParamString"); // Get common compound information std::vector<std::string> compounds = GetCompoundsList(); //only one compound in task6, so only one element in compounds array double molarMass = GetCompoundConstant(compounds[0], MOLAR_MASS); double critTemp = GetCompoundConstant(compounds[0], CRITICAL_TEMPERATURE); double density = GetCompoundTPDProp(compounds[0], DENSITY, 273, 1e5); // Get tolerance double absTol = GetAbsTolerance(); double relTol = GetRelTolerance(); // Get overall properties of streams and holdups double massFlow = pInStream->GetMassFlow(2, BASIS_MASS); double massHoldup = pHoldup->GetMass(5, BASIS_MASS); double outTemp = pOutStream->GetTemperature(15); double molarMassHoldup = pHoldup->GetOverallProperty(1, MOLAR_MASS); // Get solid distribution information std::vector<double> PSD_b3 = pHoldup->GetPSD(50, PSD_Q3); std::vector<double> PSD_s3 = pHoldup->GetPSD(50, PSD_q3); }

Test your unit in Dyssol:

Build the solution by Build → Build Solution and run Dyssol by Debug → Start Debugging.

Change the flowsheet from example of steady-state unit to be able to test new unit: remove units Out2, Out3 and streams Out2, Out3.

Change unit model MySplitter to Basics. Set unit parameters as ParamTD =

1.2, ParamConst =1e-8.Run the simulation, make sure the simulation is finished and save the obtained flowsheet as Task6. Close Dyssol.

Extend the

Simulatefunction with the code to obtain values of unit’s and streams’ parameters, which are specified in the table at the end of this section.Use breakpoints in debug mode of Visual Studio to obtain values of variables at runtime. To do this, place a breakpoint at the end of the function

Simulate(select desired line of code, then choose Debug → Toggle Breakpoint or press F9) and start debugging (Debug → Start Debugging or F5). After pressing the Simulate button in Dyssol, the program stops at the breakpoint. Values of all previously calculated variables will be available on mouse hover in Visual Studio. Compare your results with expected values below.Unit parameters:

Parameter

Function

Expected value

Value of Time-dependent unit parameter ParamTD at time point 5s

GetTDParameterValue()1.2

Value of constant unit parameter ParamConst

GetConstParameterValue()1E-8

Value of string unit parameter ParamString

GetStringParameterValue()Initial value

Common compounds information:

Parameter

Function

Expected value

List of defined compounds

GetCompoundsList()4031BC62EC7F17EFA33F

Molar mass of the first defined compound

GetCompoundConstant(… MOLAR_MASS)0.06

Critical temperature of the first defined compound

GetCompoundConstant(… CRITICAL_TEMPERATURE)3500

Density of the first compound by T = 273 K, P = 1e+5 Pa

GetCompoundTPDProp(… DENSITY, …)1600

Tolerances:

Parameter

Function

Expected value

Global absolute tolerance

GetAbsTolerance()1E-6

Global relative tolerance

GetRelTolerance()0.001

Overall properties of streams and holdups:

Parameter

Function

Expected value

Mass flow of the inlet at t = 2 s

pInStream->GetMassFlow()1

Mass of the holdup at t = 5 s

pHoldup->GetMass()5

Temperature of the outlet at t = 15 s

pOutStream->GetTemperature()300

Molar mass of the holdup at t = 1 s

pHoldup->GetOverallProperty()0.06

Note

You will see the outlet temperature at 15 s is not changed to 320 K. In this process, only

_dStartTimeand_dEndTimeare defined in the simulation (due to the simulation file of a steady-state process), the time point t = 15 s is not defined and thus no change will take place. If you add a time point for the outlet stream,pOutStream->AddTimePoint(15);

the temperature will change to 320 K at t = 15 s.

Therefore, please pay attention to your time points during the dynamic simulation. A time point must be defined in advance, at which your simulation is performed. However, in most cases, the time points during a simulation are calculated by the solvers and you don’t need to define them extra.

Note

You can also observe the temperature change at

_dEndTimeto 320 K, like the code below:pOutStream->CopyFromHoldup(pHoldup, _dStartTime, 1); pOutStream->SetTemperature(_dEndTime, 320); // ... intermediate code ... // double outTemp = pOutStream->GetTemperature(_dEndTime);

In this case, the outlet temperature is still 300 K. The reason is that the default value of variable

DeleteDataAfterinCopyFromHoldupistrue, which means the information at copied time (here_dStartTime) is kept and those afterwards are deleted. Since there is no information at_dEndTime, the program returns the temperature at_dStartTime.If you set the value of variable

DeleteDataAftertofalse, the outlet temperature doesn’t change either, because only the holdup information at_dStartTimeis copied, which has nothing to do with that at_dEndTime. You must also copy the holdup info at the end in order to change the temperature at the end.pOutStream->CopyFromHoldup(pHoldup, _dStartTime, 1, false); pOutStream->CopyFromHoldup(pHoldup, _dEndTime, 1); pOutStream->SetTemperature(_dEndTime, 320); // ... intermediate code ... // double outTemp = pOutStream->GetTemperature(_dEndTime);

For developing dynamic units in Dyssol, don’t forget to treat your parameter at different time points separately.

Solid distributed properties and PSD of streams and holdups:

Parameter

Function

Expected value

\(Q_3\) distribution of the holdup at t = 50 s

pHoldup->GetPSD(… PSD_Q3)(not applicable)

\(q_3\) distribution of the holdup at t = 50 s

pHoldup->GetPSD(… PSD_q3)(not applicable)

Development of dynamic units with internal DAE solver

You can solve systems of DAE automatically in Dyssol system. In this case, the unit should contain one or several additional objects of CDAEModel class. This class is used to describe DAE systems and can be automatically solved by class CDAESolver.

Unit::Unit()

Constructor of the unit: called only once when unit is added to the flowsheet. In this function a set of parameters should be specified:

Basic info:

m_sUnitName: Name of the unit that will be displayed in Dyssol.m_sAuthorName: Unit’s author.m_sUniqueID: Unique identificator of the unit. Simulation environment distinguishes different units with the help of this identificator. You must ensure that ID of your unit is unique. This ID can be created manually or using GUID-generator of Visual Studio (Tools → GUID Genarator).

Specify ports: add new, rename or delete existing.

If unit has some additionally parameters, than specify them here.

Internal holdups and additional material streams can be defined here.

All other operations, which should take place only once during the unit’s creation.

Unit::~Unit()

Destructor of the unit: called only once when unit is removed from the flowsheet. Here all memory which has been previously allocated in the constructor should be freed.

Unit::Initialize(double _dTime)

Unit‘s initialization. This function is called only once at the start of the simulation. Starting from this point, information about defined compounds, phases, distributions, etc. are available for the unit. Here you can create state variables and initialize some additionaly objects (e.g. holdups, material streams or state variables).

In this function, variables of all DAEModels should be specified by using function AddDAEVariable; connection between CDAEModel and CDAESolver classes should be created by calling function SetModel.

Unit::Simulate(double _dStartTime, double _dEndTime)

Dynamic calculation for a specified time interval. Is called for each time window on simulation interval. Calculation of the defined DAE-system can be run here by calling function DAESolver::Calculate().

Unit::SaveState()

For flowsheets containing recycled streams, SaveState() function is called when the convergence on the current time interval is reached, this also ensures the return to the previous state of the unit if convergence fails during the calculation. Here all internal time-dependent variables which weren’t added to the unit by using AddStateVariable, AddMaterialStream or AddHoldup functions should be manually saved. Implementation of this function is not obligatory and can be skipped.

Unit::LoadState()

Load last state of the unit which has been saved with SaveState() function. Implementation of this function is not obligatory and can be skipped.

Unit::Finalize()

Unit‘s finalization. This function is called only once at the end of the simulation. Here one can perform closing and cleaning operations to prepare for the next possible simulation run. Implementation of this function is not obligatory and can be skipped.

DAEModel::CalculateResiduals(double _dTime, double* _pVars, double* _pDers, double* _pRes, void* _pUserData)

Here the DAE system should be specified in implicit form. This function will be called by solver automatically.

DAEModel::ResultsHandler(double _dTime, double* _pVars, double* _pDers, void* _pUserData)

Handling of results, which are returned from DAESolver on each time point. Called by solver every time when the solution in a new time point is ready.

Application example

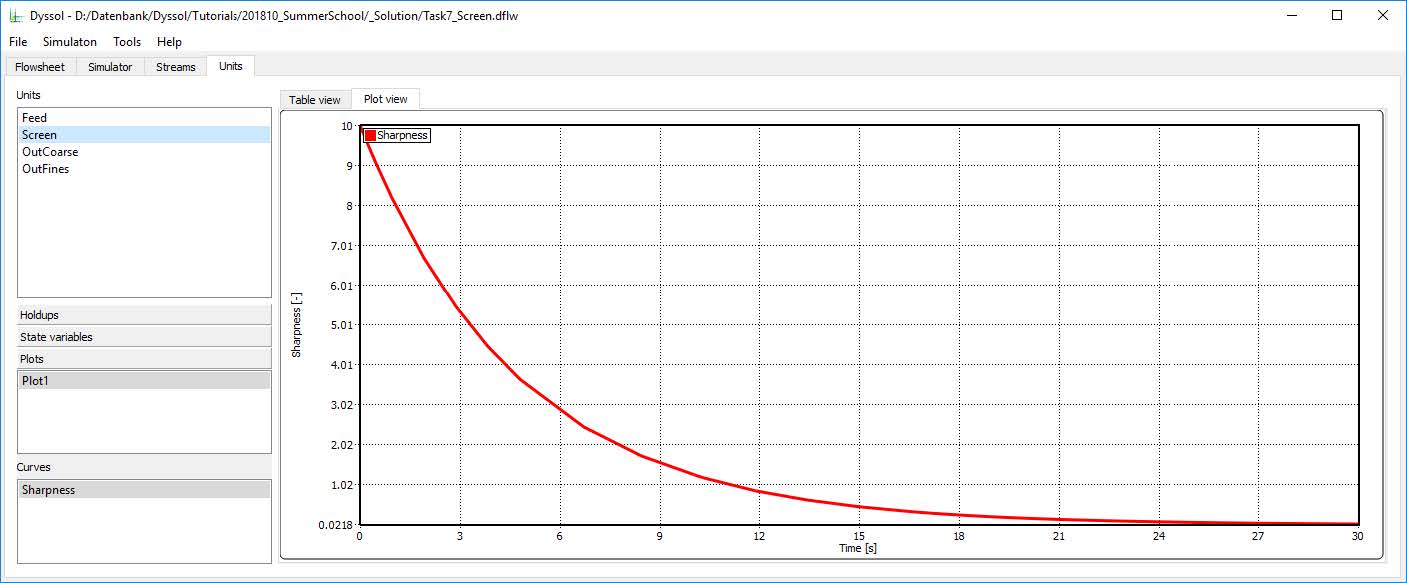

In this example, you will learn how to develop a dynamic screen model with a holdup, wherein the screening efficiency reduces with time and also depends on the holdup‘s mass. Additionally, the time dependency of screening efficiency should be plotted.

The screening efficiency is calculated according to the equation below:

To complete the simulation, you need to solve the following dynamic equation system:

Note

Notations:

\(\alpha\) – separation sharpness (specified by user)

\(x_{cut}\) – cut size (specified by user)

\(\dot{m}_{out}\) – output mass flow (specified by user)

\(k_1\) – time-dependent sharpness reduction factor [\(s^{-1}\)] (specified by user)

\(k_2\) – mass-dependent sharpness reduction factor [\(kg^{-1}\)] (specified by user)

\(G(x_i)\) – screening efficiency for particle of size class \(i\)

\(\dot{m}_c\) – mass flow of coarse particles

\(\dot{m}_f\) – mass flow of fines particles

\(\dot{m}_{in}\) – input mass flow

\(M_h\) – holdup mass

\(x_i\) – particle diameter

Now you need the following steps:

Copy the directory with the template unit

<PathToSolution>\ModelsCreatorSDK\UnitsTemplates\DynamicWithDAESolver\to the directory for new units<PathToSolution>\ModelsCreatorSDK\Units\. Rename the folder toScreenTemplateand the fileDynamicWithDAESolver.vcxprojtoScreen.vcxproj.Along with this application example, you obtain a pre-configured template folder of the air classifier unit

...\Task7\ScreenTemplate\, in which you find the source fileUnit.cppand header fileUnit.h. Copy the contents of them to the correspondingUnit.cppandUnit.hfiles in your template folder<PathToSolution>\ModelsCreatorSDK\Units\ScreenTemplate\.Open the template solution

<PathToSolution>\ModelsCreatorSDK\Dyssol.slnin Visual Studio.Add project with your new unit to the solution: select File → Add → Existing Project and specify path to the project file

<PathToSolution>\ModelsCreatorSDK\Units\ScreenTemplate\. Rename the unit toUnit_Screen.Open

Unit_AirClassifier→Unit.cppand extend the unit with the following functionality:

Edit the unit

CUnit:Modify constructor

CUnit():Specify unit’s name by changing value of variable

m_sUnitNametoDynamic screen. This name will appear in the drop-down list for unit types in Dyssol simulation.Specify author’s name by changing the value of the variable

m_sAuthorName.For

m_sUniqueID, unlike the examples in steady-state unit, DO NOT change the ID, because the given ID is connected with the simulation file provided. If you change the ID, the parameter in simulation file would not be read by Dyssol and you can’t carry out your simulaiton.Add unit parameters: add 5 constant unit parameters using

AddConstParameterand set their initial values according to your wish:0 ≤

alpha≤ 1000 ≤

Xcut≤ 10 ≤

Mout≤ 1000 ≤

k1≤10 ≤

k2≤ 1

Now your constructor code looks like this:

CUnit::CUnit() { // Basic unit's info m_sUnitName = "Dynamic Screen"; m_sAuthorName = "Your name"; m_sUniqueID = "C7755DAF619C448D863D1CBCC13648BC"; // DO NOT change this ID // Add ports AddPort("Input", INPUT_PORT); AddPort("Coarse", OUTPUT_PORT); AddPort("Fines", OUTPUT_PORT); // Add unit parameters AddConstParameter("alpha", 0, 100, 1, "Separation sharpness"); // alpha AddConstParameter("Xcut", 0, 1, 0, "Cut size [m]"); // Xcut AddConstParameter("Mout", 0, 100, 0, "Output mass flow [kg/s]"); // Mout AddConstParameter("k1", 0, 1, 0, "Time-dependent sharpness reduction factor [1/s]"); // k1 AddConstParameter("k2", 0, 1, 0.001, "Mass-dependent sharpness reduction factor [1/kg]"); // k2 // Add holdups AddHoldup("Holdup"); // Set this unit as user data of model m_Model.SetUserData(this); }

Modify function

Initialize(double _dTime):Check flowsheet parameters: raise errors (

RaiseError) if distribution by size (IsDistributionDefined) and the solid phase (IsPhaseDefined) are not defined.Add plots: add a plot with the name “Plot1” to show dependency of the separation sharpness (Y axis is “Sharpness”) over time (X axis is “Time”). Add a curve on this plot with the name “Sharpness”. Use functions

AddPlot,AddCurveOnPlot.Add state variables to the model: add differential and algebraic variables (

AddDAEVariable), which will be calculated by the internal DAE solver (see equations above). Set all initial values to 0.Differential variable for the holdup mass

Holdup(already defined);Differential variable for the separation sharpness

alpha;Algebraic variable for the output mass flow

Mout.

The example code for this function is shown below.

void CUnit::Initialize(double _dTime) { // Check flowsheet parameters if (!IsDistributionDefined(DISTR_SIZE)) { RaiseError("Size distribution has not been defined!"); } if (!IsPhaseDefined(SOA_SOLID)) { RaiseError("Solid phase has not been defined!"); } // Add plots AddPlot("Plot1", "Time [s]", "Sharpness [-]"); AddCurveOnPlot("Plot1", "Sharpness"); // Clear all state variables in model m_Model.ClearVariables(); // Add state variables to a model m_Model.AddDAEVariable(true, GetHoldup("Holdup")->GetMass(_dTime), 0); // holdup mass m_Model.AddDAEVariable(true, GetConstParameterValue("alpha"), 0); // separation sharpness m_Model.AddDAEVariable(false, GetConstParameterValue("Mout"), 0); // output mass flow // Set tolerances to model m_Model.SetTolerance(GetRelTolerance() * 10, GetAbsTolerance() * 10); // Set model to a solver if (!m_Solver.SetModel(&m_Model)) { RaiseError(m_Solver.GetError()); } }

Edit the solver

CMyDAEModel:Modify function

CalculateResiduals(double _dTime, double* _pVars, double* _pDers, double* _pRes, void* _pUserData): this function computes the problem residual for given values of the independent variable_dTime, state vector_pVars(defined variables from 7.3), and their derivatives_pDerivs. Here the DAE system itself must be specified in implicit form.Get pointers to streams: obtain pointer to holdup for further work with its parameters:

GetHoldup.Get values of input and internal parameters: obtain current values of:

unit parameters \(k_1\), \(k_2\), \(\dot{m}_{out}\) (

unit->GetConstParameterValue())mass flow of the inlet at current time point (

inStream->GetMassFlow())mass in the holdup at current time point (

holdup->GetMass())

Calculate and set residuals: calculate residuals of all variables from 7.2 according to equations above:

_pVars[0]– calculated value of the holdup mass \(M_h\)_pVars[1]– calculated value of the separation sharpness \(\alpha\)_pVars[2]– calculated value of the output mass flow \(\dot{m}_{out}\).

The example code is shown below.

void CMyDAEModel::CalculateResiduals(double _dTime, double* _pVars, double* _pDers, double* _pRes, void* _pUserData) { // Get pointers to streams CUnit *unit = static_cast<CUnit*>(_pUserData); CMaterialStream *inStream = unit->GetPortStream("Input"); // Input CHoldup *holdup = unit->GetHoldup("Holdup"); // Holdup // Get time parameters double prevTime = holdup->GetLastTimePoint(); double dTime = _dTime - prevTime; // Get values of input and internal parameters double k1 = unit->GetConstParameterValue("k1"); // k1 double k2 = unit->GetConstParameterValue("k2"); // k2 double mOut = unit->GetConstParameterValue("Mout"); // Mout double mIn = inStream->GetMassFlow(_dTime); // Mass flow in inlet double MhPrev = holdup->GetMass(prevTime); // Mass in holdup // Calculate and set residuals double derMassHoldup = mIn - mOut; double derAlpha = (-_pVars[1] * k1 - _pVars[1] * (MhPrev + derMassHoldup)*k2); double valMassFlowOut; if (mOut * dTime < _pVars[0]) { valMassFlowOut = mOut; } else { valMassFlowOut = mIn; } _pRes[0] = _pDers[0] - derMassHoldup; _pRes[1] = _pDers[1] - derAlpha; _pRes[2] = _pVars[2] - valMassFlowOut; }

Modify function

ResultsHandler(double _dTime, double* _pVars, double* _pDerivs, void *_pUserData): this function processes the results returned by the solver at each calculated step. Is called by solver every time, when the solution in the new time point is ready.Get pointers to streams: obtain pointers to streams

Input,CoarseandFines, as well as to holdupHoldupfor further work with their parameters (use functionsGetPortStreamandGetHoldup).Add points on plot: put value of the separation sharpness \(\alpha\) (calculated by the DAE solver in

_pVars[1]) on the curve “Sharpness” of the plot “Plot1”. Use the functionAddPointOnCurve().Mix the input stream with the holdup: use the function

AddStreamto add the content of the inlet between time pointsholdup->GetLastTimePoint()and_dTimeto the holdup.Calculate transformation matrices: calculate values of the screening efficiency \(G(x_i)\) to fill in two transformation matrices:

THoldupToFines– to transform holdup into the output of fines material. All elements NOT on diagonal are zero. \(G(x_i)\) of classe \(i\) locates at position \((i,i)\).THoldupToCoarse– to transform holdup into the output of coarse material. All elements NOT on diagonal are zero. The value \(1-G(x_i)\) of classe \(i\) locates at position \((i,i)\).Here also fractions of mass streams of coarse and fines outlets must be calculated according to the grade efficiency \(G(x_i)\). The screen unit of Plitt’s model can be used as a reference.

Copy the holdup to the output streams: copy all parameters of the holdup into the both outlet streams using function

CopyFromHoldupand set their new mass flows, calculated by the DAE solver in_pVars[2]. This calculated mass must be previously scaled according to the grade efficiency \(G(x_i)\).Apply transformation matrices: apply transformation of the PSD to the outputs, using the function

ApplyTM.Set new mass to the holdup, using the function

SetMass. It is calculated by the DAE solver in_pVars[0].

The example code looks like this:

void CMyDAEModel::ResultsHandler(double _dTime,double* _pVars, double* _pDerivs, void *_pUserData) { // Get pointers to streams CUnit *unit = static_cast<CUnit*>(_pUserData); CMaterialStream *inStream = unit->GetPortStream("Input"); // Input CMaterialStream *outStreamC = unit->GetPortStream("Coarse"); // Coarse CMaterialStream *outStreamF = unit->GetPortStream("Fines"); // Fines CHoldup *holdup = unit->GetHoldup("Holdup"); // Holdup // Get values of unit parameters at current time point double xCut = unit->GetConstParameterValue("Xcut"); double Mh = _pVars[0]; double alpha = _pVars[1]; double mFlowOut = _pVars[2]; // Add points on plot unit->AddPointOnCurve("Plot1", "Sharpness", _dTime, alpha); // Mix input stream with holdup holdup->AddStream(inStream, holdup->GetLastTimePoint(), _dTime); // Obtain parameters for PSD calculation unsigned classesNum = unit->GetClassesNumber(DISTR_SIZE); std::vector<double> x = unit->GetPSDMeanDiameters(); std::vector<double> holdupPSD = holdup->GetPSD(_dTime, PSD_MassFrac); // Setup transformation matrices CTransformMatrix THoldupToCoarse(DISTR_SIZE, classesNum); CTransformMatrix THoldupToFines(DISTR_SIZE, classesNum); // Calculate transformation matrices double massFactor = 0; for (unsigned i = 0; i < classesNum; i++) { for (unsigned j = 0; j < classesNum; j++) { if (i == j) { // if this is a diagonal element double val = 1 / (1 + std::pow(xCut / x[i], 2.0) * std::exp(alpha * (1 - (std::pow(x[i] / xCut, 2.0))))); THoldupToCoarse.SetValue(i, j, val); THoldupToFines.SetValue(i, j, 1 - val); massFactor = massFactor + holdupPSD[i] * val; } } } // Copy holdup to output streams outStreamC->CopyFromHoldup(holdup, _dTime, mFlowOut*massFactor); outStreamF->CopyFromHoldup(holdup, _dTime, mFlowOut*(1 - massFactor)); // Apply transformation matrix outStreamC->ApplyTM(_dTime, THoldupToCoarse); outStreamF->ApplyTM(_dTime, THoldupToFines); // Set new mass to the holdup holdup->SetMass(_dTime, Mh); }

Test your unit in Dyssol:

Build the solution and run Dyssol: Build → Build Solution, and then Debug → Start Debugging.

Use exemplary flowsheet

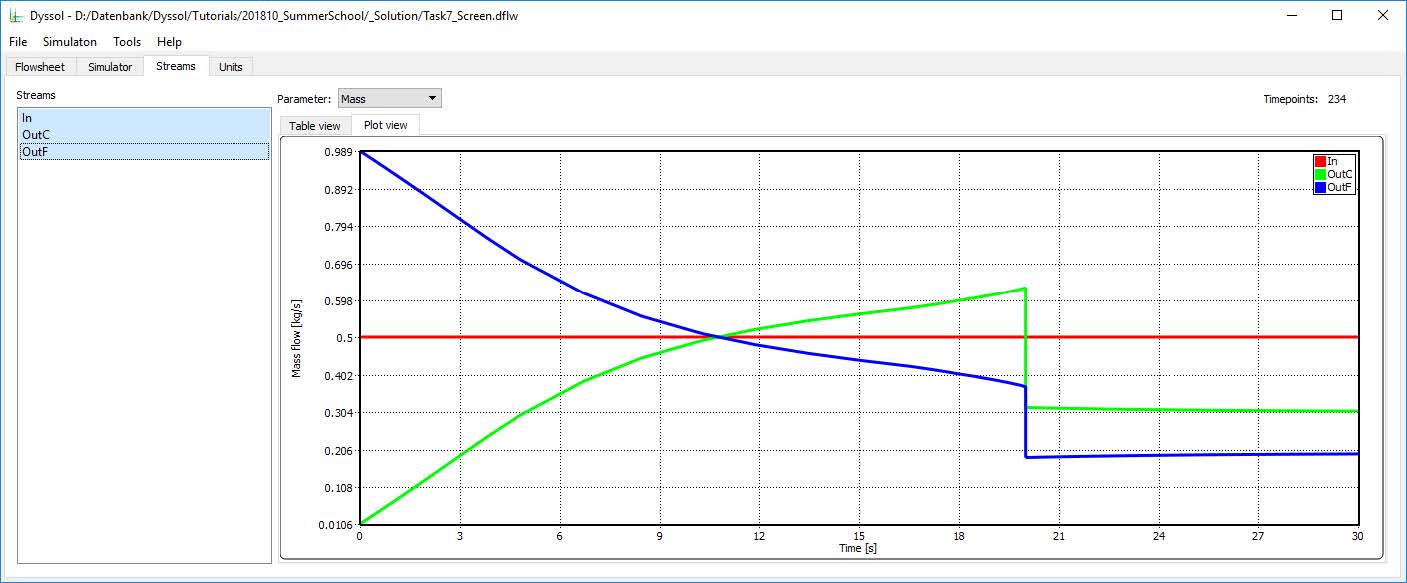

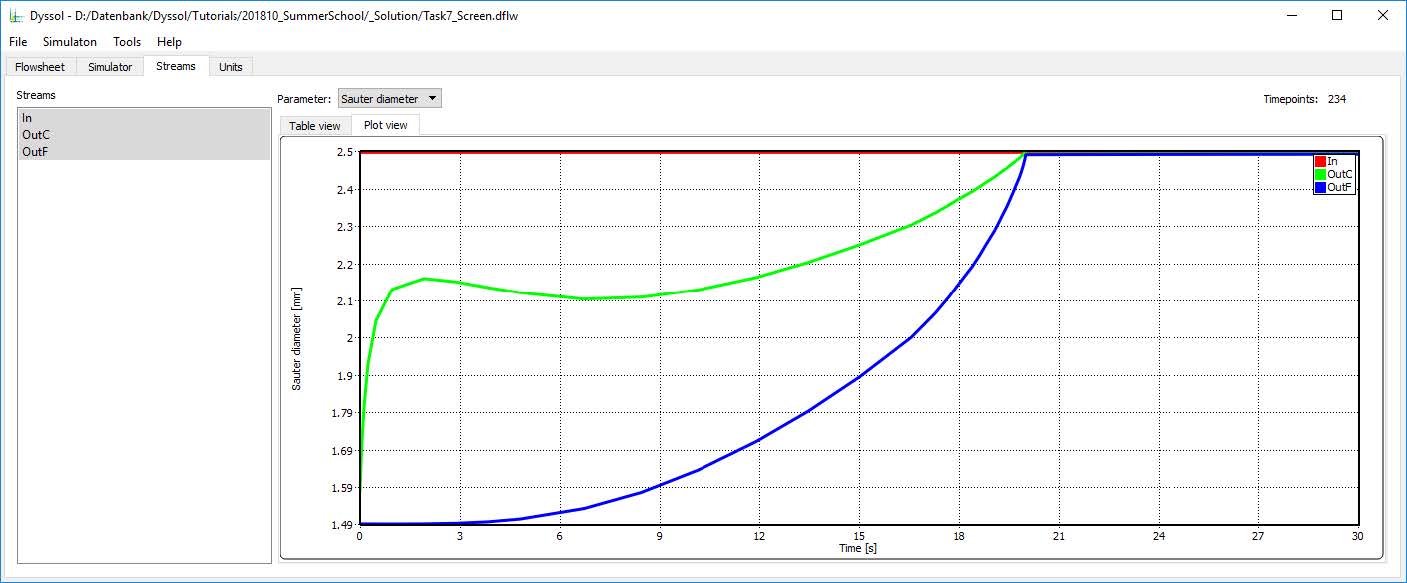

...\Task7\DynamicScreen.dflwto test your unit. Compare your results with the expected ones in the figures below.

Configure unit to work with MATLAB

You can use MATLAB Engine API in Dyssol during the development of solvers. It requires an installed 32-bit version of MATLAB. For API description please refer to C Matrix API.

To enable interaction with MATLAB configure template project with your unit, do as follows:

Add a new environment variable in Windows with the path to the MATLAB installation directory:

Computer → Properties → Advanced system settings → Environment variables → System variables → New

Variable Name:

MATLAB_PATH.Variable value: path to installed 32-bit version of MATLAB (e.g.

C:\Program Files (x86)\MATLAB\R2014b). It may require restarting the Visual Studio or computer to apply changes.Provide the main project of template solution with path to MATLAB libraries:

Select project

ModelsAPIin solution explorer, then choose Project → Properties → Configuration Properties → Environment, set combo box Configuration in the top of the window to position All Configurations and provide the Environment field with parameterPATH=$(MATLAB_PATH)\bin\win32.Provide unit’s project with the path to MATLAB libraries:

Select project with your unit in solution explorer, then choose Project → Properties → Configuration Properties → Environment, set combo box Configuration in the top of the window to position All Configurations and provide the Environment field with parameter

PATH=$(MATLAB_PATH)\bin\win32.Add MATLAB libraries to the unit’s project:

Select project with your unit in solution explorer, then choose Project → Properties → Configuration Properties → Linker → Input → Additional Dependencies, set combo box Configuration in the top of the window to position All Configurations and add following four libraries at the beginning of the input field:

libmx.lib,libmat.lib,libeng.lib,libmex.lib.Insert MATLAB’s header in

Unit.h: add the line#include "engine.h"to the include section at the top of yourUnit.hfile.

Solver development

You must do the following in order to develop your new solver (plese refer to Configuration of Visual Studio project template):

Install Microsoft Visual Studio 2015 (Community).

Configure template project

ModelsCreatorSDK.

After builiding your own new solvers, the functionality of them can be applied in all units by adding them as unit parameters.

Basically, all solvers have a set of constant functions and parameters, which are available in each new solver (Base solver). and a set of specific ones, which depend on the solver’s type. New types of solvers can be added upon request and will include a set of parameters and functions that are needed to solve a specific problem.

You can implement several solvers of one type (e.g. with different models) and then choose a specific one to use it in unit by user interface, please refer to section Unit parameters in Models API.

Please notice that in the current version of Dyssol, only Agglomeration solvers is available for solver development. The following solvers are implemented by means of open-source libraries connected to Dyssol and thus cannot be developed by yourself.

DAE solver for dynamic units

Non-linear solver for steady-state units

Add new solver to the template project

Copy the desired template of the unit from

<PathToSolution>\ModelsCreatorSDK\SolversTemplatesto the folderSolversin solution (<PathToSolution>\ModelsCreatorSDK\Solvers).Rename template’s folder according to the name of your new solver (further

<MySolverFolder>). The name can be chosen freely.Rename project files in template’s folder (

*.vcxproj,*.vcxproj.filters) according to the name of the new solver.Run the solution file (

<PathToSolution>\Dyssol.sln) to open it in Visual Studio.Add project with your new solver to the solution. To do this, select in Visual Studio File → Add → Existing Project and specify path to the project file:

<PathToSolution>\ModelsCreatorSDK\Solvers\<MySolverFolder>\<*.vcxproj>.Rename added project in Visual Studio according to the name of your solver.

Now you can implement functionality of your new solver. The list of available functions depends on type of selected solver.

To build your solution press F7, to run it in debug mode press F5. Files with new solvers will be placed to <PathToSolution>\ModelsCreatorSDK\Debug.

As debug versions of compiled and built solvers contain a lot of additional information, which is used by Visual Studio to perform debugging, their calculation efficiency can be dramatically low. Thus, for the simulation purposes, solvers should be built in Release mode.

Configure Dyssol to work with implemented solvers

Build your solvers in Release mode. To do this, open your solution in Visual Studio (run file

<PathToSolution>\ModelsCreatorSDK.sln), switch Solution configuration combo box from the toolbox of Visual Studio from Debug to Release and build the project (press F7 or choose Build → Build project in program menu).Configure Dyssol by adding the path to new solvers: run Dyssol, choose Tools → Options → Model manager and add path to your solvers (

<PathToSolution>\ModelsCreatorSDK\Release).

Now all new developed units will be available in Dyssol.

In general, usual configuration of Model manager should include following path for solvers:

<InstallationPath>\Solvers\: list of standard solvers;

<PathToSolution>\ModelsCreatorSDK\SolversDebugLibs\: debug versions of standard solvers;

<PathToSolution>\ModelsCreatorSDK\Debug\: debug versions of developed solvers;

<PathToSolution>\ModelsCreatorSDK\Release\: release versions of developed solvers.

Development of agglomeration solver

Please refer to the background information Agglomeration solver and Agglomeration solvers when necessary.

Solver::Solver()

Constructor of the solver: called only once when solver is added to the unit. In this function, a set of parameters should be specified:

Basic info:

m_solverName: Name of the solver that will be displayed in Dyssol.m_authorName: Solver’s author.m_solverUniqueKey: Unique identificator of the solver. Simulation environment distinguishes different solvers with the help of this identificator. You must ensure that ID of your solver is unique. This ID can be created manually or using GUID-generator of Visual Studio (Tools → GUID Genarator).

All operations, which should take place only once during the solver’s creation.

Solver::~Solver()

Destructor of the solver: called only once when solver is removed from the unit. Here all memory which has been previously allocated in the constructor should be freed.

Solver::Initialize(vector<double> grid, double betta0, EKernels kernel, size_t rank, vector<double> params)

Solver‘s initialization. This function is called only once for each simulation during the initialization of unit. All operations, which should take place only once after the solver’s creation should be implemented here. Implementation of this function is not obligatory and can be skipped.

Solver::Calculate(vector<double> N, vector<double> BRate, vector<double> DRate)

Calculation of birth and death rates depending on particle size distribution. All logic of the solver must be implemented here.

Solver::Finalize()

Solver‘s finalization. This function is called only once for each simulation during the finalization of unti. Here one can perform closing and cleaning operations to prepare for the next possible simulation run. Implementation of this function is not obligatory and can be skipped.

Configure solver to work with MATLAB

You can use MATLAB Engine API in Dyssol during the development of solvers. It requires an installed 32-bit version of MATLAB. For API description please refer to C Matrix API.

To enable interaction with MATLAB configure template project with your solver, do as follows:

Add a new environment variable in Windows with the path to the MATLAB installation directory:

Computer → Properties → Advanced system settings → Environment variables → System variables → New

Variable Name:

MATLAB_PATH.Variable value: path to installed 32-bit version of MATLAB (e.g.

C:\Program Files (x86)\MATLAB\R2014b). It may require restarting the Visual Studio or computer to apply changes.Provide the main project of template solution with path to MATLAB libraries:

Select project

ModelsAPIin solution explorer, then choose Project → Properties → Configuration Properties → Environment, set combo box Configuration in the top of the window to position All Configurations and provide the Environment field with parameterPATH=$(MATLAB_PATH)\bin\win32.Provide solver’s project with the path to MATLAB libraries:

Select project with your solver in solution explorer, then choose Project → Properties → Configuration Properties → Environment, set combo box Configuration in the top of the window to position All Configurations and provide the Environment field with parameter

PATH=$(MATLAB_PATH)\bin\win32.Add MATLAB libraries to the solver’s project:

Select project with your solver in solution explorer, then choose Project → Properties → Configuration Properties → Linker → Input → Additional Dependencies, set combo box Configuration in the top of the window to position All Configurations and add following four libraries at the beginning of the input field:

libmx.lib,libmat.lib,libeng.lib,libmex.lib.Insert MATLAB’s header in

Solver.h: add the line#include "engine.h"to the include section at the top of yourSolver.hfile.