Bunker

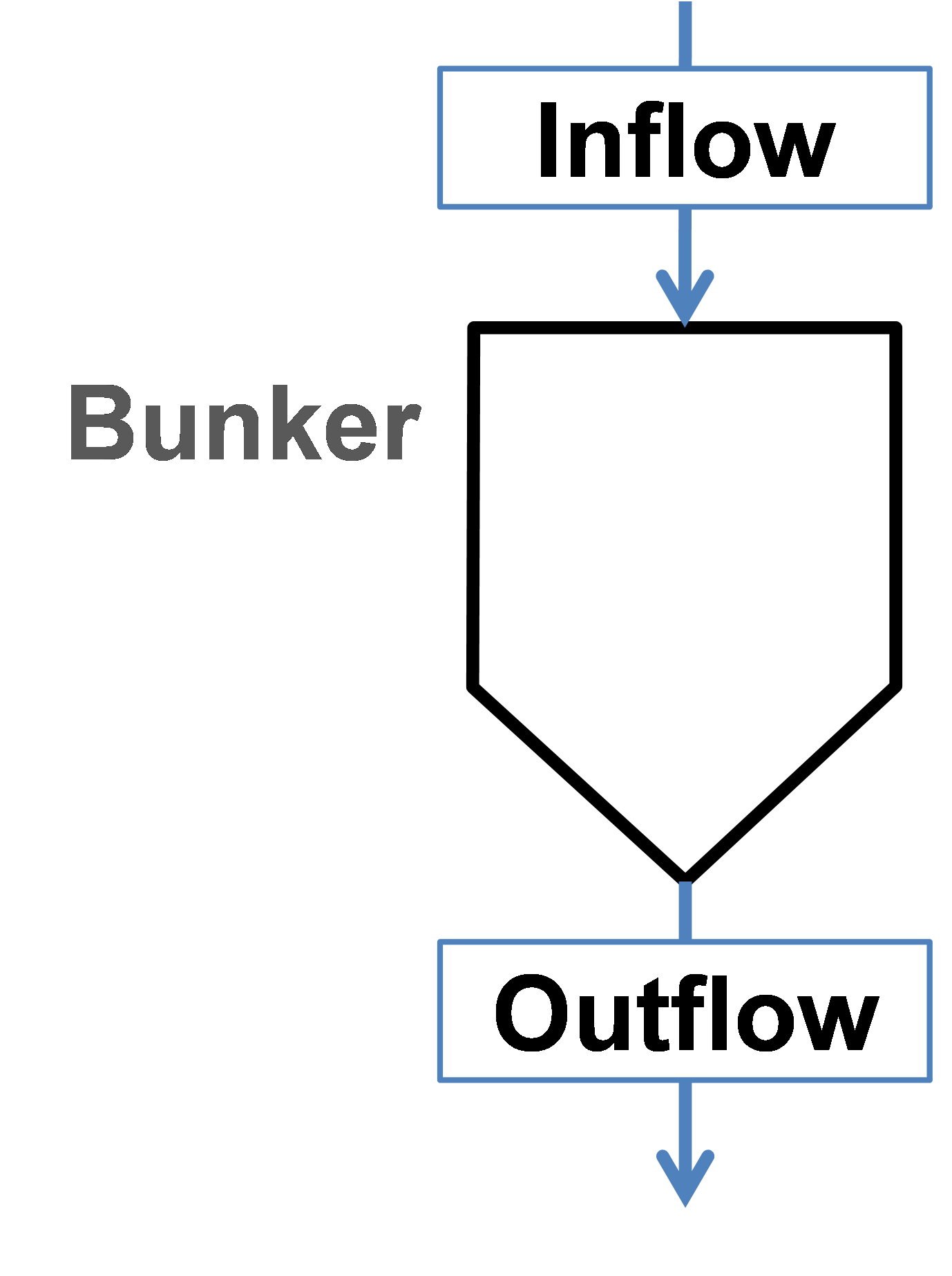

Bunker unit performs accumulation of the solid part of the input material with ideal mixing, see figure below.

The model takes into account only the solid phase, the rest of the phases are bypassed.

Two models for the bunker outflow are available:

Adaptive: User defines only the target mass

of the bunker and

is being adjusted by the system to match the user-defined target mass

, depending on inflow mass

, current bunker mass

and

: .

Constant: User defines timepoints with the desired bunker outflow

. The system tries to provide this outflow, if enough material

is in bunker. Otherwise the

. The smoothing function is implemented to let the numerical solver provide reliable results:

To correctly take into account the dynamics of the process, norms of each overall parameter (mass flow, temperature, pressure) are maintained as:

For compounds fractions:

For each distributed parameter:

Note

Notations:

– current mass inside the bunker

– target mass inside the bunker

– solids input mass flow

– solids output mass flow

– value of an overall parameter at time point

– mass fraction at time point

– number of defined compounds

– number of classes in distribution

Note

Solid phase is required for the simulation.

Note

Input parameters needed for the simulation:

Name |

Description |

Units |

Boundaries |

|---|---|---|---|

Target mass |

Target mass within the bunker |

[kg] |

Target mass > 0 |

Relative tolerance |

Relative tolerance for DAE solver |

[-] |

>0 (0 for flowsheet-wide value) |

Absolute tolerance |

Absolute tolerance for DAE solver |

[-] |

>0 (0 for flowsheet-wide value) |

See also

a demostration file at Example Flowsheets/Units/Bunker.dlfw.